One of the tricky aspects to catch in product design is the amount of true value in it between its stages of evolution. Sometimes, last year's model that you bought could have negligible difference in it as opposed to this year's. Its marketing might say its improved, with a new recipe, new look, new shape and so on and in the end, you would probably pay a premium for it as well, all for the same exact thing.

On the other hand, as a credit to product design, it could also be that last year's model could be insufficient for use compared to the current year's release. Dangerous too. So is this really a credit if people are still using last year's product?

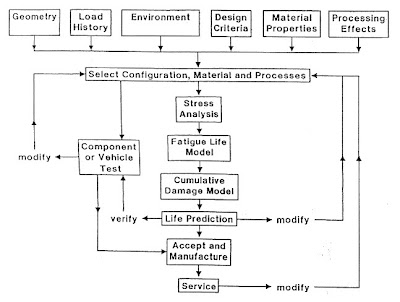

Subsystem design is very dependent on the performance of the parent system. Today's illustration is a case in point.

Speedplay's marketing line for the "Platformer" brand of pedal adapters is this :

"The innovative Speedplay Platformer is a user-friendly, tool-free platform cover for Zero and Light Action pedals. The Platformer makes it easy to convert from clipless pedals to platforms for riding with street shoes."

But reality is different. Last year's clear "Light Action" pedal adapters are

really light action, apparently.

As the internet will show, quite a number of people are disappointed with the quality of material used in its design. Durability issues notwithstanding, riding your bike with one of these installed could be a danger just waiting to happen

Among the disgruntled is an individual (who doesn't wish to be named) whose adapters broke just as he was pulling out of a traffic light last summer. Casual riding wasn't light enough for Platformers. The plastic adapter on his right pedal broke catastrophically with an audible snap. Because of little warning, he lost his balance very quickly and ended up crashing on his tailbone and elbow, right in the middle of a road during rush hour traffic. A crucial red light to one side gave him enough time to get back up in pain, pick up the pieces and vacate the road.

Thanks to light action pedal adapters, he is in miserable condition today. Because a fractured coccyx is an injury with

no form of available treatment other than time, five months later he still is in immense pain on a daily basis and can’t sit for more than an hour without feeling discomfort. He calls the sensation "intensely searing". For the weekend racer and an enthusiastic bike geek that he is, this is not exactly

the good life.

The gravity of the injury and the possibility that someone else could be hurt in similar fashion made him contact Speedplay on many occasions. To make sure this wasn't some freak event, he even installed a set of the old Platformers on his girlfriend's bike as well.

The product lasted approximately 16 minutes before they cracked. Some insults are better off when they come with forewarning. This one was even recorded on video by him.

Speedplay took back his pedals for inspection and has stuck by the quality of their brand. They chose to deny his theories of why they broke and didn't feel much need to return them back to him. They have claimed no responsibility for his injuries and other damaged personal articles. The user has now fixed a date with a Small Claims Court to settle the matter in the interest of full disclosure. He has also had a meeting with the

Consumer Product Safety Commission.

Interestingly enough, this year's design, with the new "recipe" doesn't seem to have had as many problems since it does not use the same plastic clamshell (see right). The user ordered a pair from Competitive Cyclist, rode them on his girlfriend's spin bike for 50 minutes (the approximate lifespan of the broken ones) and they seemed to hold up just fine.

I suppose somewhere, someone found out the trouble with the old pair, fixed it, moved on. Meanwhile, old units are still being used by riders.

A Plausible Theory

The concept behind the Speedplay Platformer is to allow the user the option of riding a bicycle equipped with Speedplay brand pedals without having to wear dedicated cycling specific shoes. By creating a larger, stable platform around the pedal, Speedplay Platformers, allow the user to ride in “regular shoes."

A set of Speedplay Platformers consists of six pieces. A complete, individual unit is comprised of two seemingly identical pieces of clear plastic. The difference between the two pieces is found on the “inside” where four tabs fit together in a male/female manner. A metal retaining clip slides through these tabs and locks the Platformer in place around the Speedplay pedal.

Because of this design and the fact that the Platformer is molded to be compatible with only one specific type of pedal, it is virtually impossible for the Platformers to be installed incorrectly. They are either locked in place or they aren’t and this is very obvious to the user. To remove a Platformer, a key, coin, or screwdriver is used to remove the metal retaining clip by sliding the clip from the Platformer. The edge of each Platformer is concaved to facilitate the easy removal of the retaining clip.

At the time the user tried the product, he was 210 pounds and stood a height of 6'1". While this isn't typical of your featherweight climbing maestro, he told me that he's never broken any products before and he's always careful with cycling equipment.

Now clipping in and clipping out of Speedplay pedals cause substantial wear on these high performance pedals as most of us have learned. The right pedal, more so due to clipping bias in start-stops. The user's had between 3000-4000 miles of usage on them. For most people, this is a season's worth of use.

This leads to a plausible theory for why the pedals failed. He wrote to me :

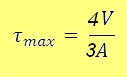

My theory for why they broke is because design of the Platformer didn't take into account worn pedals as they are molded around a brand new set of pedals. Since the pedals I was using were worn down, there was some open space between the Platformer and the pedal itself which lead to much more stress on the Platformer particularly on the "outside."

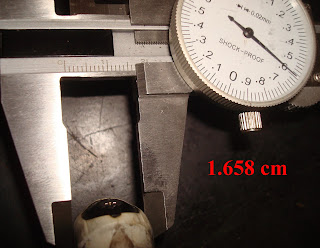

The following two images show a 3.2% reduction in right side pedal dimension between a brand new and the user's old one.

New right pedal

The following image, of the used left side pedal, shows a 1% difference in pedal dimensions when compared to the right side pedal. This shows that the right pedal wears more due to clipping bias.

Please be aware of this problem and report any of your personal mis-happenings in the comments section. If you also wish to offer any kind words of advice to the user with regards to a broken tailbone, please share your thoughts.

* * *