A reader who doesn't wish to be named sent me an email with this image. What is shown here is apparently a right side Crank Brothers Candy 'C' pedal that failed on an indoor Revmaster stationary bike. Good for him it was indoors, and the fact that the bike is built with safety features for holding onto something when falling in embarrassment.

The user estimated that he would have put a little more than 100 hours of time on these pedals, all during home use at fairly low pedaling intensities. He is a fairly big person, at 6'2" and weighing 217 pounds.

When it broke, he had been standing on the pedals for want of some variation and was putting forth moderate effort. But he remarked that despite cycling since the 1980's, this is the first pedal he has ever broken. He has other Crank Brothers pedals in stock for outdoor riding but this event has diminished his confidence in those as well. Natural.

The pedal features a chromoly spindle. I do not know its geometrical specifications. Curious enough, I visited the Crank Brothers website (its very well developed actually, so Kudos to them!) and obtained a screen-shot of the spindle from one of their servicing videos. The failure, as I see it, happened just where the cross section started to step down :

Loads & Stresses : The spindle acts like a simplistic cantilever beam with the concentrated reaction force R and pedal force F as I show below.

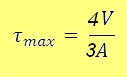

Then, for a solid spindle acting like a beam, maximum shear stress at the neutral axis would be about :

where V is shear force and A is the cross sectional area of the round section.

By looking at the length of the spindle above compared to its depth (L>>d), one might be able to say that what would be more concerning than the shear stress itself is the spindle's bending stress at one or two critical locations (sites where part sees high stress risers). The designer would then multiply the concentration factors necessary for these stress risers to the equation for maximum bending stress at the spindle's outer fiber given by :

where c = outer radius of section, M = bending moment & I = moment of inertia

High Cycle Fatigue (HCF) : Since the user told me that he uses this moderately at home, the correct technique to analyze the spindle would be in HCF, in a mode of fluctuating loads. Here, the stresses seen would be much below the yield of the spindle material but the loading would gradually accumulate until failure. This happens because of local yielding at critically stressed locations.

To generate a rough idea of fluctuating load on the spindle, I made some assumptions. Research has shown that a good figure for average pedal force for long periods is about 1/5th of body weight. If this is the average, then an approx. max force could perhaps be 75% of body weight. So for a 217 lb person riding moderately like the individual here, a possible range of forces could be as follows :

Fig.1 : Peak forces are seen roughly when the crank is forward, 90-100 degrees past top dead center. These peak forces are a resultant of effective force (radial) and ineffective forces (tangential). For specific illustration, mean component of foot load, Fm, is 43.4 lb and in tension. The alternating component is given by Fa = (Fmax - Fmin) /2 = 119.4 lb. Mean and alternating components of the reaction force Rm and Ra is same as for the foot loading forces. Time period is given by t = 1/frequency. Note : Blue region for upstroke has been exaggerated whereas in reality, peak magnitude might not be so high.

Fig.1 : Peak forces are seen roughly when the crank is forward, 90-100 degrees past top dead center. These peak forces are a resultant of effective force (radial) and ineffective forces (tangential). For specific illustration, mean component of foot load, Fm, is 43.4 lb and in tension. The alternating component is given by Fa = (Fmax - Fmin) /2 = 119.4 lb. Mean and alternating components of the reaction force Rm and Ra is same as for the foot loading forces. Time period is given by t = 1/frequency. Note : Blue region for upstroke has been exaggerated whereas in reality, peak magnitude might not be so high.The shear and bending stresses can then be derived from these alternating and mean loads. A Von Mises stress calculation can be done for both alternating and mean stresses. These V M stresses can then be plotted on a modified Goodman diagram along with the corrected endurance limit and yield strength to check visually where in relation to failure boundaries this pair of stresses lie. The safety factor of the part in service comes specifically due to how this pair of stresses vary with each other.

Since the material is steel with a knee in the S-N diagram, a good estimate for design pedal life for infinite life in steel would be a capability to withstand the maximum stresses shown in the figure above for 2 million cycles and over. A normal 90 RPM cadence equates to 1.5 Hz frequency or 1.5 cycles/second. So a designer can make a pedal spindle with chromoly to sustain itself for the range of life shown below.

2 million cycles / (1.5 cycles/sec) = 1.3 million seconds = 370.37 hrs.

200 million cycles / (1.5 cycles/sec) = 133.3 million seconds = 37037.03 hrs.

If a company has the time and money, they'll design for higher life than 200 million cycles.

The point I'm trying to make here is that given the rough loading curve for one rider above you, the actual pedal spindle would have had to be designed to withstand much higher amplitudes of stress cycles for many different riders across a broad spectrum. This should also arrive after providing for fudge factors to account for geometrical & environmental influences!

However in this case, the spindle locally yielded at lower stresses in a matter of 100 hours of life to failure. This was in a controlled environment. This does not correspond suitably with the range for HCF life calculated. On the surface, it appears the spindle might not have been designed/manufactured properly which brought down the strength of the spindle considerably from its predicted life.

What do you think? Should the pedal spindle be beefed up in size to accommodate heavier people, designed with milder cross-sectional variations or heat treated appropriately to overcome this dangerous scenario? And what are your experiences with this particular pedal?

RELATED RESOURCES :

4130 Normalized Steel Alloy Material Properties

Spindle Shear & A Related Injury

Falling Out of Love With Crank Brother's Pedals

Integrated Sensors In Intelligent Bike Parts

How A Clipless Pedal Works

Scary looking pedal. Interestingly I never bothered to see what an actual spindle looks like? Are all of them of this size?

ReplyDeleteMatt :

ReplyDeleteThe spindle design should be specific to the product. For example, Shimano's spindle looks much more sturdier. Compare it with the Candy C.

The spindles are actually solid. I suspect the stress concentration due to the step up let to the failure. It appears there is a chamfer, but in this case wasn't enough. Maybe that spindle had faulty machining (such as a groove or notch) at that point. It could even something created from the spinning pedal.

ReplyDeleteFrom the picture it looks like a fatigue failure to me. There looks to be a smooth area at the top of the spindle and then a jagged area that the bottom that represents the ultimate failure. With a better image you might be able to see the growth of the fatigue crack (it would like like tree rings) and use the fracture area to get some idea of the load that resulted in the final failure.

I also had one of these fail. Unfortunately for me it was in rush hour traffic setting off on a roundabout on my fixed. Still can't believe I made it round.

DeleteWhen I inspected the fracture I could see that there had been a crack in the metal, only about 1mm deep which would have caused high stresses at that point. I put it down to a manufacturing problem with my pedal as I've done tens, possibly hundreds of thousands of miles on CB pedals.

Ron:

ReplyDeleteI think if you took the outer casing and the needle bearing off the spindle, the Shimano one would be similarly small. You can't tell anything about the spindle from that picture.

Hightower : Thanks. You're right. I overlooked the fact that the Shimano spindle wasn't uninstalled. You can't make these things any bigger than what they look like huh? Wow. Oh, and thank heavens they're solid! Yet even that didn't make the cut here.

ReplyDeleteFYI : Left pedal spindle has a groove on it for identification. But that might be inconsequential? From the image, I'm positive it looks like the right pedal that broke.

ReplyDeletehttp://techdocs.shimano.com/media/techdocs/content/cycle/EV/actionsports/PD/EV-PD-6700-2939_v1_m56577569830696869.pdf

ReplyDeleteThis shows you the spindle and everything inside that pic from Ron.

Even looks like they have some stress risers as well.

And they use chromoly too? Its kind of sad that none of these folks publish basic dimensions. You're hard pressed for information.

ReplyDeleteIMO - Now you can boast to friends you did the famous Lance Armstrong emasculating pedal slip while climbing.

ReplyDeleteRon,

ReplyDeleteThere have been some complaints lately that the spindles have some side to side play on them due to wear of the bearing races. Did the OP note any play and if so, it may have led to a possible scoring of the surface to initiate the crack. I have used a Quattro without problems but have not tried the C's, since I have Shimano to cover my "rain" biking.

Crank Brothers explicitly state there is no rider weight limit for the steel axle versions of the pedal. There are a lot in service, and this is just one failure. Searching for broken Crank Bros Candy pedals brings up a lot of tales of spring breakage, but not many spindle breaks, and some of those include reports of impact prior to breakage. In short, no need to panic, this looks like an outlier which can be found in any mass produced product. Imagine how expensive pedals would be if they had to be inspected and tested to aircraft standards to eliminate the early failures.

ReplyDeleteSo you're okay with an "outlier" resulting in injury to someone?

ReplyDeleteThe failure from your photo of both pedals seems to show a fatigue

ReplyDeletefailure judging from the white fracture and the darker grey part that is about 1/3 the diameter. That means there was a crack with a sharp discontinuity at its leading edge that finally cracked all at once leaving a "clean" fracture.

I don't have the part but it fracture appears to start from a

circumferential notch. That it broke at this diameter speaks well for the slender part of the shaft that doesn't taper rapidly to the main diameter. Does the egg beater rotate on the spindle? If so, the wear groove would be a likely starter for such a failure. I have not seen

one of these disassembled after use so I know little about their wear marks and machining smoothness. It is not a shear failure.

A close-up of the fracture face and the OD of the dark to light face would show a difference in the surface between fracture start and the rest, possibly showing a wear mark that if active would have been hot and weak. There's lots to be seen if you can imagine yourself as a healthy spindle.

Ron said...

ReplyDeleteSo you're okay with an "outlier" resulting in injury to someone?

As an alternative to paying $500 a pair for basic pedals, yes. To get to the kind of low failure rate you seem to want would require the kind of test and examination protocols currently applied to aircraft. It simply doesn't make economic sense; it's cheaper to pay out compensation for the very small number of injuries attributable to premature failure caused by manufacturing defects than to cut the failure rate any further. If a lot of these spindles were failing in normal service within a couple of years of installation, it would be worth looking at the design, and maybe recalling them as Look did with similar failures on the early production Keo pedals, but one anecdote is not a data set on which to base such a decision.

Perhaps if companies spend less on marketing hoopla and more into SPC, we would see better products.

ReplyDeleteAnon @ 6:42 : You do make sense but the truth of the matter is something entirely different. When you get a chance, read what Prof. Wilson, author of Bicycling Science, wrote about lousy products in the bike industry. When you're on the receiving end of the "anecdote" , perspectives change quickly. Even Jobst Brandt has said many times that these companies are "too poor" to pay for good engineers. That comes from his personal experience.

ReplyDelete"Even Jobst Brandt has said many times that these companies are "too poor" to pay for good engineers"

ReplyDeleteWhere is the money supposed to come from? Either cyclists are too poor to pay for good engineering, or they would rather spend their money on attributes other than safety/reliability, or just maybe they have rationally evaluated the cost benefit ratio of attempting to cut failure rates to vanishingly low levels and are prepared to take their chances. I know the last of these is almost certainly wrong, but rational actors would either accept the economic argument or refuse to get on their bicycles. What really happens is that cyclists behave irrationally about risk, just like pretty much everybody else. Most of the time, they don't care about the compromises in the design economy, figuring bad stuff won't happen to them even though the product is manifestly too cheap to be really safe, and then periodically they panic out of all proportion to the true risk when they stumble upon one anecdote such as the one under discussion.

There are some badly engineered products out there, if our only way of differentiating "good" from "bad" is MTBF, but cyclists want their components light, cheap, and in the case of pedal spindles small diameter for biomechanical reasons. As the oft repeated maxim goes:

Light, cheap, strong - pick any two.

I'd like to have thought that spending more money on something equals getting a solidly made product. But I think you maybe confusing expensive with strong. Its not always that way is it? Many of the failures I document on my blog are usually expensive products that are brought down in weight so much that they're structurally sketchy in design.

ReplyDeleteAnd is it always the consumer who's setting ridiculous prices for gear? Think about it. Bikes and bike rentals are expensive, jerseys are expensive, components are pricey, a bicycle chain costs 40-60 dollars, a pair of socks costs 20 bucks and above, a cycling jacket costs 200 bucks and over, and you can easily spend over a 100 dollars on just a mini tool, a pedal wrench and a floor pump! So I'm not so sure whether customers are always setting these prices. And then we complain we can't bring more people in cycling. Well, you have one reason why.

I'd like to have thought that spending more money on something equals getting a solidly made product. But I think you maybe confusing expensive with strong. Its not always that way is it? Many of the failures I document on my blog are usually expensive products that are brought down in weight so much that they're structurally sketchy in design.

ReplyDeleteAnd is it always the consumer who's setting ridiculous prices for gear? Think about it. Bikes and bike rentals are expensive, jerseys are expensive, components are pricey, a bicycle chain costs 40-60 dollars, a pair of socks costs 20 bucks and above, a cycling jacket costs 200 bucks and over, and you can easily spend over a 100 dollars on just a mini tool, a pedal wrench and a floor pump! So I'm not so sure whether customers are always setting these prices. And then we complain we can't attract more people into cycling. Well, you have one reason why.

Its complicated for sure. People want cheap stuff but they can't handle something from China or Taiwan, they're very nervous about injuring themselves with shoddy products but they want to go lightweight for performance, and cycling companies don't compromise and sell some ridiculously expensive stuff but which also don't stand the test of time.

FYI : In the post, I changed the equation for maximum shear stress which will now be 4/3 * (V/A) for a round section, as people told me that this was a solid spindle.

ReplyDeleteThis is where I think the new Metrigear powermeter might meet its nemesis. Thats a lot of money in precision electronics to have broken.

ReplyDeleteRon said...

ReplyDelete"But I think you maybe confusing expensive with strong. Its not always that way is it?"

I don't think I'm the one who is confused. I know expensive doesn't necessarily mean reliable - the money has usually gone on things other than making the most reliable product possible. What is the case is that a reliable product, in the terms under discussion, will necessarily be expensive. You call for more reliable product, and in the next breath you complain that cycling is too expensive.

"And is it always the consumer who's setting ridiculous prices for gear?"

Yes, it always is. Nobody held a gun to my head to make me spend $300 on a pair of cycling shoes, I struck a bargain in a reasonably free market with a vendor whose product I felt was worth that much of my money.

We're discussing leisure cycling, which is an entirely optional pastime for people who have both the time and the money to amuse themselves with it. They choose equipment according to a set of rational and irrational criteria, and we have to leave them to take their own view about how much they want to spend on reliability. If there was an outcry for $500 (or whatever the profitable market price would be for such a thing) pedals which would never* break in normal service, somebody would step in to fill the market. We already have numerous manufacturers filling the niche for pedals which are advertised as barely adequate for use by adult American males of median weight, and at a price premium over their stronger variants.

It is good that there are people like you and Jobst Brandt analysing failures and drawing attention to poor design or poor process control when it leads to unacceptable failure rates, but not every failure is unacceptable. Some of them are down to poor design which could be fixed at no extra cost in either material or performance, but many are not; the cost of fixing the problem with more material or more testing and examination during manufacture imposes either an unsustainable economic cost or an unacceptable diminution in performance, both of which amount to the same thing, a product for which there is no market.

Before condemning a product, it would be as well to establish what the actual failure rate is, and just as important, to determine the acceptable failure rate for the class of product. We all know that the acceptable failure rate for handlebar stems is much lower than the acceptable failure rate for tyres, because a snapped stem is a much bigger deal than a puncture, yet the acceptable failure rate for stems is still non-zero because they sometimes fail but we keep riding, even on products where samples are known to have failed in service.

*say 1 failure per million pedals in the first 2000 hours of service.

You make complete sense. I always thought that sometimes, push must come to shove if you want to see my work as condemnation for failure rates (by the way, calculating or researching failure rates is not my job). Many brilliant people who have also been observers of these companies have noticed in most cases the latter pays lip service to safety issues, neither do they entertain someone's genuine recommendations for change in design. At the end of the day, question is what you care about more - market or customers. No customers = no market anyway, as it works both ways!

ReplyDeleteI have had a crank arm break off in the middle of a club ride. I didn't hit the road with much speed because it was on a climb. I am guessing a faulty Crank Bros pedal would also fail on an uphill. You might get a bruise or scrape and have to pedal home with one leg. And you wouldn't lose much pedal-wise, since these "disposable" pedals are only designed to last one year. What I have found is that the sleeve bearing can score the spindle, and Crank Brothers refuses to replace the spindle (at any cost). I have sent a note to Crank Brothers today asking them to improve their design.

ReplyDeleteArne :

ReplyDeleteThats pretty unfortunate that happened to you. I find it a good thing that I started this topic so we can collect people's experience with this pedal. Please feel free to post some pics of it. I too think that the spindle has a problem, but can't pinpoint if its the bearings that is scoring it and creating a stress riser. Do you have evidence of scoring action?

Yes, it is a common occurance for these pedals(Eggbeater and Candy)... I have seen 3 cases on spindles failing among my local riding group. Replaced for free by manufacturer, but still not safe for aggressive mtb riding.

ReplyDeleteIt's the only pedal i've ever seen fail in such a way.

It is worth noting that the 2010 Eggbeaters have a redesigned spindle and thus bearing system.

ReplyDeleteEggbeaters develop significant play in the bearing shell that goes onto the spindle and I think that can introduce scoring or similar that increase failure as someone else mentioned. These things really need to be maintained via simple rebuild every year.

Which brings me to my point. There is a big set of factors interplaying here when it comes to bikes:

1) Bikes are limited to be human powered, you can't slap a massive safety factor onto everything you design without ending up with a very heavy machine being sold in a very weight conscious market.

2) Company overhead versus sales volume. "High performance" bikes don't sell fantastic volumes. Branded companies have huge overheads in terms of sales, advertising, staff, etc. Then you have the distributor overhead and then you have the retail outlet overhead.

The actual cost, especially in a market dominated by a few OEM manufacturers selling to most branded "manufacturers" - is comparatively miniscule.

3) What the market will bear - there is a fair amount of psychological inflation

4) End user care - most cyclists, even ones with advanced engineering degrees don't necessarily maintain their equipment optimally, especially when it comes to bearing systems and the like. For users with no technical background the mechanic overhead can be exorbitant and IMO out of the price range of many people.

The whole environment of cycling is full of problems - but then so is the automotive industry which has far deeper pockets for engineering teams and much greater volume sales (therefore per unit costs of advertising, etc are lower).

On Saturday July 31st 2010 riding my schwinn 2008 peloton carbon road bike with slate grey candy c pedals on Glendora Ridge Road, California. At 9.30am I stand up to pedal on a flat stage - I suddenly hit the ground like a ton of bricks! My right collar bone is broken in two places - caused by right side candy pedal shearing off at spindle point of failure shown in your post above - I have ridden other crank bros pedals where the bearings have come loose but never this kind of catastrophic failure! I have pictures of the pedals - if you are interested.

ReplyDeleteWilliam Johnston - wjohnston1@gmail.com

I had a similar pair of pedals fail in the same way. 2008 Candy C pedals failed in 2009 on my cross bike during a fast uphill.

ReplyDeleteFor what it's worth, the pedals were at that time sold with a stated weight limit when I bought them, and I exceed that limit. Crank Borthers was nice enough to send me a rebuild kit at no cost, when I explained the circumstances.

I have snapped off other pedals too (Shimanos and others over the years) so it's not just the Crank Brothers parts. Stuff breaks, especially if you are a fast clydesdale rider like myself. Luckily I haven't been hurt badly by any of them.

As a mechanical engineer, I was surpised to see how thin the spindle was inside the shaft. That step down in diameter and chamfer do seem to be the problem. It's a pity that in cycling, parts seem to come in two flavors, cheap or light. I rarely have the option to spend a premium on reliability. Personally at 220-230 lbs and riding for fun, shaving 5 oz off my bike does me little good.

Perhaps as the commuter market grows, manufacturers will see the value in selling high-quality parts to market whom value running efficiently mile after mile, rain or shine, with little maintenance or up-keep.

-Shlepzig

I've had two eggbeaters fail by breaking off at the threaded portion at the end, not in the way described here.

ReplyDeletehttp://www.flickr.com/photos/swoo/3071557355/

Shimano 737 pedals did the same thing after many years of service.

I'm very late to this party. I thought I'd add a November, 2012 story to this post.

ReplyDeleteAbout a week ago, I crashed my bike. My right Egg Beater pedal released my cleat as I pulled up, while standing. The bike tilted right, the pedal probably struck the ground, and as the bike came to an abrupt halt, I flipped over the handlebars, which broke my collarbone and my right wrist. The latter injury is bad enough that it was operated on yesterday, and I'll apparently lose some motion.

What happened exactly? There was some movement in the clamping mechanism that holds the cleats in place. The big spring on the spindle is supposed to keep the clamps held tightly closed. It would have done that, but two of the clamps - they are attached to each other - weren't mounted rigidly at their base on the pedal.

I don't know if they pedals came that way, or if they suddenly failed. Perhaps my cleats wore down enough to allow the slop in the clamps to take me down, although that's not my fault.

I have four other pairs of Egg Beaters on four other bikes. None have the problem of the one right pedal on the bike I crashed on, nor does the left pedal on that bike. Mileage on the pedals is well under 500 miles.

While I've got an appointment with an attorney, I'm probably going to forget about this. I do have medical insurance, but it's cost me some income and there are medical costs I do have to eat, plus the $1000+ ambulance ride to the hospital, some new bike parts, etc.

I certainly hope this doesn't happen to anyone else and I plan to notify Crank Brothers about the issue, and ask for some compensation - not that I expect to get any without an attorney.