Those Chinese made Crank Brothers Candy C pedals, whose flaws we discussed in an earlier post, has obtained another victim. The pedal failed in the same area again. A reader, who describes himself as a relatively non-litigious person, emailed me his story with pics of his injuries along with the broken pedal spindle. He describes this as a serious design flaw and wrote that had he crashed while going downhill at speed instead of the top of the hill he was riding on, he may not have lived to tell the tale.

Some good people had noticed his crash and rushed to get him to a hospital. There, he would find out that he had broken his right clavicle in two places, not to mention extensive bruises and abrasions. "It hurts like hell, inspite of Vicadin", he wrote. The healing process takes 8 weeks, or 2 months. How would you feel if your summer was ruined like this? We do hope him a quick recovery.

Fatigue is the biggest limiter of products whose design goal is to take cyclic loads and is often the prime reason for failure. Overlooking the design or manufacture of such items to combat accumulated fatigue leads to reduction of its life prematurely, that may result in serious injury or death. A rough back of the envelope calculation of mean and alternating stresses in a pedal spindle was done by me in the previous post for perspective.

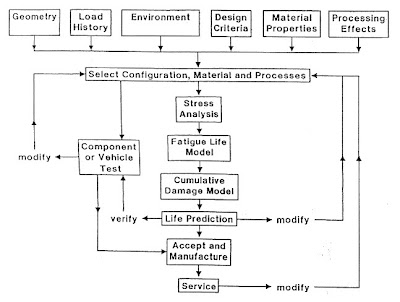

Simply relying on safety factors alone does not take care of this important issue. The synergistic effects of product design geometry, heat treatment, loads imposed, environment, residual stress and time can all reduce the lifetime of a product. It is common practice to see companies show off their computer skills with exquisitely colorful FEA. This is not the end to the fatigue design process either. Verification has to be absolutely thorough. If you don't test the item, which is for public use, by simulating real world conditions, you can be held guilty of negligence.

This is the flowchart that the SAE likes to follow for designing against fatigue. Observe that the word "modify" shows up in three different spots.

How safe do you want to be? I hear that something like one major air accident everyday is considered a 99% safety rate as far as air travel goes. Anyway, the company Crank Brothers has babysat the individual in question with a new pair of Candy C's. Everything is safe. Don't you worry, here's a band-aid. This was just another outlier.

* * *

I've seen quite a number of broken Candy C pedals - a few at the spindle, and several more with broken springs. The pedals remain popular because as you pointed out, Crank Bros customer service is quick to 'take care of the problem' by giving out new pedals; and because they heavily sponsor domestic cyclocross racing. It's too bad they break, because people seem to like them, but they break a lot.

ReplyDeleteLooking at the other post there seems to be some doubt as to what's causing the failures, here's my theory as I have a pair or pretty worn Eggbeaters under my desk, let me know if you need more info.

ReplyDeleteOk, the body assembly looks to be made up of an inner bushing that's joined in some way (interference fit?) to the fixed wing, inside that is the smaller movable wing along with the spring, both of these sit on the bushing. Does that make sense? It's hard to convey in words.

There's also a plastic bushing that is a push fit inside the fixed wing that sides over the larger part of the axle (the bit with no grease in the exploded diagram in the previous post). My old pedals have developed play in the movable wing due to wear between the movable wing and the inner bushing, which is why they're toast, but also the body assemble can now move side to side along the length of the axle presumably because the end of the plastic bushing has worn against the end of the axle.

I'm getting to my point so bear with me! My theory is the worn plastic bushing has allowed the body assemble to move closer to the ridged bit (that's the technical term) causing wear and then failure.

If I remember I'll bring an 8mm socket tomorrow and take them apart further to see if I can see this happening. Having said that the axles aren't as old as the rest of the pedal as I put some shorter titanium ones on not long after I got them. Hmm, think I’ll be checking the ti axles tonight as I heard titanium is more susceptible to stress risers.

I'm somewhat shocked that in this day and age people are designing steel parts that fatigue fail after short duty cycles.

ReplyDeleteOk, I've taken some pics of my axle and the old pedals, sorry I can't figure out how to make the link clickable.

ReplyDeletehttp://picasaweb.google.co.uk/boddunn/Pedal?feat=directlink

What's not very clear in the pics is the axle has the anodising worn off half way round which seems to me to be from from the pressure of me pedaling. The is also light scoring at the point the other pedals failed.

Any questions just let me know,

Matt

I find it interesting that folks will get hurt using these faulty products and return them for replacement -- then bolt on the replacement and go riding once they've healed up! I've seen this happen with all kinds of poorly-designed bike parts over the years. Cyclists must be stupid, if you bought any other poorly designed product that failed and injured you, would you want ANOTHER ONE so you could potentially get injured again? At least you'd want a REFUND of your money along with payment for hospital bills, etc. But too often cyclists simply take the "oops, we're sorry, here's a free replacement" and go on using the junk! Amazing!

ReplyDeleteI fear my life if this happens at a busy intersection. What a shame.

ReplyDeleteBod,

ReplyDeleteI appreciate the investigation you have put into this. Those are great images. It could be wear, geometry, or materials related issue (or combination of both). To confirm, the individual in question is in consultation with a materials expert to see what his take on it is. [I must say that I'm curious myself to know what the hardness of the steel axle was]

Ron,

ReplyDeleteYou've obviously dedicated time and space to publicizing incidents of product failure that range from inconvenient to deadly.

Is it your experience that companies in the cycling industry who may have released a faulty design or otherwise-risky product step-up and try to put things right, even if it means a charge-off in the short-term, or do the play the odds and avoid even acknowledging the problem, in hopes of avoiding coordinated public scrutiny?

Lastly, do you consider yourself a cycling industry muckraker?

Gah, another failure. I am getting nervous about my pair, particularly as they've developed some bearing play.

ReplyDeleteI had a similar experience with the Candy SL, that almost killed me. The plastic end caps wore off and then the "wing" bracket that your cleats connect to broke when I attempted to bunnyhop over some rocks and sent me flying over the handle bars. I spent the rest of the day in the hospital getting re-constructive surgery on one of my knees and was out for the season.

ReplyDeleteWhat really pissed me off is Crank Brothers response. After being laid up with the injury and training for months to recover, I sent the broken pedal back to Crank Brothers. I assumed that these pedals must be defective, that the wing brackets wouldn't just break like that. That would be unsafe, right?

Not according to Crank Brothers. Apparently the plastic end caps had fallen off and therefore the pedal failed and they were not responsible. I argued that pedals that have end caps that were plastic and could simply fall off at anytime wasn't safe and should be considered defective. They had no answer and didn't care that I rode the pedals less then one year and nearly killed myself, they would not replace them. They suggested that I should pay $50 to have them upgraded or rebuilt.

I’ve have several other brand pedals that I've ridden for years and never had any kind of failure. I bought these pedal because they were light and I wanted to try something different...BIG MISTAKE.

i bought some candy c pedals late last summer. the end cap on the left pedal fell off 2 weeks in. other than that ive had no problems with these until the spindle snapped on the right pedal(the one without the missing endcap). now crank bros is accusing me of power washing my pedals and they want to charge me for a rebuild or i can pay almost what i already payed for newer pedals.

ReplyDeletereally shitty customer service so far. my local shop says they will hook me up with some cheap time pedals.

Nearly ate some road tonight, Injured but lucky enough not to have any oncoming traffic or could be dead, I've got them on all my bikes? Spinal brake CANDY C FAIL.... apparently yet again

ReplyDeleteI separated my shoulder after a Crank Brothers Mallet failure. They failed at a rate of about two spindles per year for me. All in the same place as those Candies.

ReplyDeleteThe shoulder separation is a permanent condition. I'll never ride Crank Brothers again. They supposedly have "improved" the strength of the pedals but this is not the company's MO. They make nicely packaged and anodized junk. It's like packaging a turd in a gold box.

Ok.. so I had the same problem with a pair of Candy C pedals.. IN my case I didn't wreck but I did slash my leg open and needed 10 stitches. Did anyone have any luck getting the crank brothers to pay for the hospital bills or has anyone tried?

ReplyDeletehttps://www.box.com/s/3dzsp0kp1vhh9clg6n98

Ok.. so I had the same problem with a pair of Candy C pedals.. IN my case I didn't wreck but I did slash my leg open and needed 10 stitches. Did anyone have any luck getting the crank brothers to pay for the hospital bills or has anyone tried? They also upgraded me to a new set of mallets along with replacing some grips i have only had a few months.

ReplyDeletehttps://www.box.com/s/3dzsp0kp1vhh9clg6n98